Great success with remote commissioning

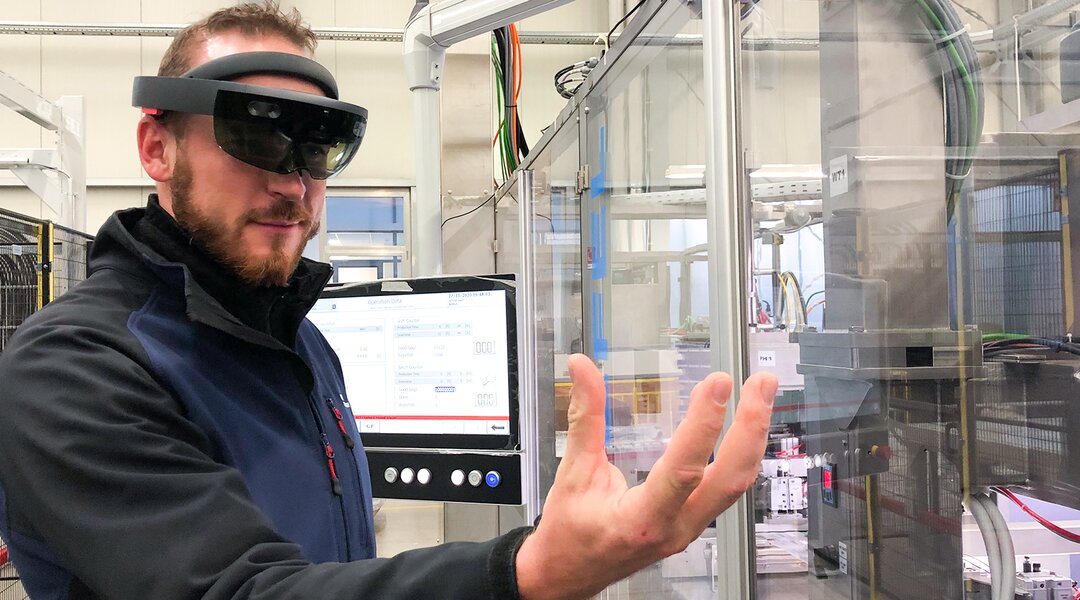

Our industry experts provide insights into how commissioning works with the help of digital solutions.

As our customers’ partner for every single process step, we aim to support our customers as reliably as ever, even in times of Corona! This turned out to be particularly challenging at the beginning of the contact restrictions with regard to the commissioning of our machines: Since our technicians, depending on the regulations in the customer company, could in many cases not be on site, Kiefel has established digital options to carry out the process remotely to the same standard. Representatives of our three industries – Packaging, Medical and Service – provide insights in the following interview.

1) How often has Kiefel carried out remote commissioning?

Mathias Bachmair (Medical): In recent years, remote options were used on a case-by-case basis, and for almost every project in 2020.

Olaf Tanner (Packaging): The first remote commissioning during the pandemic was a KMD 78 for the production of trays for a customer in Israel in April 2020. So far, 10 systems have been commissioned online for the packaging division.

Franz Hogger (Service): In the service division, we have been utilizing online diagnostic tools for remote maintenance for over 20 years. We use this to remotely connect to the customer’s machines in order to view parameters and, if necessary, to correct errors. We support our customers in this way almost every day.

2) What media are used for communication during commissioning?

Olaf Tanner (Packaging): In order to make remote commissioning as clearly and tangible as possible for us and for the customer, we install cameras on the machines for live broadcasts, shoot videos that demonstrate the functionalities and continuously exchange information with our customers via various video conference tools, telephone and e-mail. We access the systems via MB-Connect, a small hardware component that provides remote access to the machine.

Franz Hogger (Service): In addition to the means already mentioned, we also access the visualization of the system via Ultra VNC Viewer.

3) What preparations are necessary for online commissioning?

Olaf Tanner (Packaging): Due to their size, our machines are disassembled into assemblies and packed for shipping after the detailed factory acceptance test via video. We therefore create photographic documentation of the packaging and shipping to make it easier for the customer to identify and localize the assemblies in the various packages. We also provide written assembly and commissioning instructions and checklists with numerous illustrations. Our customer receives support via video call throughout assembly from an expert at Kiefel who is continuously available. In particular, a stable video connection must be ensured by the customer. In addition, the usual preparations, such as providing lifting equipment, preparing the installation site and setting up the connections are necessary.

4) How long does online commissioning take compared to on-site commissioning?

Mathias Bachmair (Medical): For all sectors, this depends on the customer’s experience with our machines. Since we build many custom machines in our medical division, it can take significantly longer, depending on the concerned machine type. Online commissioning of standard machines in the packaging industry, on the other hand, only takes slightly longer.

5) How does Kiefel rule out potential dangers for plant operators and plant equipment?

Olaf Tanner (Packaging): All of our machines for all industries already contain various safety features designed to exclude potential dangers. The safety equipment instruction takes place jointly. The customer walks through the relevant points on the system with a mobile camera, with the Kiefel expert practically looking over his shoulder, giving relevant explanations and answering questions. The functioning of the safety devices is checked with the customer. The customer then acknowledges this with their signature. Naturally, all safety-relevant items are also listed in the operating instructions.

Franz Hogger (Service): We communicate with customers via MB-Connect, which is an absolutely secure system. Changes to the parameters are only imported when the safety circuit is open. It should also be mentioned that we only remotely monitor while the machine is running, but do not actively intervene in the operation of the system – the customer retains control over the machine.

6) What experiences has Kiefel made with online commissioning?

Olaf Tanner (Packaging): A first service visit has now been made to some of the machines, and the technicians have found the systems to be in perfect condition. Remote commissioning, our way, works!

Mathias Bachmair (Medical): The experiences we have gained through increased online commissioning have led us to appreciate the advantages of multiple simultaneous camera perspectives of the machine. This gives both sides a comprehensive picture, even on a very large system.

On the basis of our consistently positive experiences, we will continue to encourage our customers to take advantage of these opportunities. As a machine manufacturer, it is our mission to alleviate customers’ doubts and to offer the greatest possible transparency in the process.